Working with Old Plates

Warning!! Boring Technical Blog Post

Sometimes we store offset litho plates we’ve used, thinking, “maybe we’ll do a reprint of this one”.

Rarely do we do a reprint…

But we’re in the process of getting around to reprinting the popular Mapping Sydney prints of Jane Shadbolt, and also those of Naomi Stead, Katrina Schlunke and Trina Day.

We still have the plates from way back in 2009 when we produced a non-editioned set of these works for a show at UTS.

Yesterday, when we retrieved the Sydney Letters plate, it looked pretty rough. It still had old ink on it, which we couldn’t remove with our normal plate cleaner (“gum washout”), and it looked like it hadn’t been “gummed” before going into storage.

Usually this means that the non-printing areas of the old plate have been exposed to air, and thus corroded, and the ink will be attracted to the raw metal corroded ‘pits’.

When we tried to print it (as part of the process of testing whether we needed to get new plates made), the non-print areas of the plate were indeed ‘dirty’ – and we were getting specks and smudges transferred to the blanket and thus the paper.

Louise and I were resigned to the idea of having to chuck out the plate and get a new one made.

But before we gave up entirely, I googled “lithographic plate corrosion” and found this fabulous name for our problem: Ink Dot Scum…

Ink Dot Scum:

A printing problem found on aluminum plates used in offset lithography characterized by thousands of tiny, inked dots in non-image portions of the plate. Ink dot scum is caused by corrosion of the aluminum, which forms thousands of tiny pits that, when the film of fountain solution wears off, fill with ink.

The corrosion is commonly caused by adding a layer of water to the surface of the plate and allowing it to evaporate slowly, providing enough time for oxidation of the metal surface to occur. It is also found frequently in a band corresponding to the position of a wet dampening roller.

If the scumming is caught in time, and its effects are still localized within a small region of the plate, a solution of phosphoric acid and gum arabic can be used to eliminate it. If it has progressed far, the plate may be unusable.

That sounds pretty much spot on.

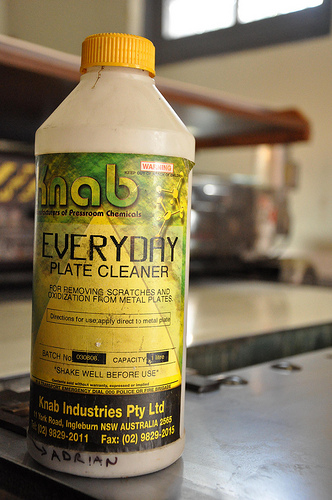

I then rummaged around in our chemical cupboard and lo and behold, I found the above bottle. (Who knows where it came from – so many of our printing supplies are “hand-me-downs” from defunct commercial printing presses).

I rang KNAB, the manufacturer, who had cleverly put their phone number on the bottle. Indeed, this stuff was a mixture of phosphoric acid and gum arabic! The very helpful fellow from Knab said it might work, depending on how far gone the corrosion was. Basically, as I understand it, the acid cuts through the ink build-up on the plate, and then a new layer of gum is put over the top. This thin gum-film stops the inking rollers from coming into contact with the corroded pits in the plate.

We tried it (clean soft rag, gently rubbing it in the areas of “Ink Dot Scum”.

It worked! The Ink Dot Scum came off, and didn’t come back.

Here endeth the lesson.

We started with zero knowledge about offset printing in 2004 when we got the Big Fag Press, and it was a steep learning curve. And we still learn something new, pretty much every time we throw the 3-phase switch and our steel monster comes shuddering to life…